No technician? No problem: Africa RISING releases 35 vernacular DIY videos on maintenance of maize shelling machines for use by farmers in Ghana

It is estimated that smallholder farmers in northern Ghana face postharvest losses ranging between 30–50% of the yields obtained in each cropping cycle. While northern Ghana has a great potential to be a breadbasket region for the country, with almost all crops grown in the country capable of being cultivated there, this high level of postharvest loss cutting across the value chains of the two main cereal crops grown in the region – rice and maize – is problematic. Previous Africa RISING studies have indicated that quantitative postharvest losses of economic importance occur in the field (15%), during processing (13–20%), and storage (15–25%).

Over the past eight years, the Africa RISING project has been working to tackle the challenge of postharvest food losses faced by farmers at each of the three critical stages – field, processing and storage. In the field, the project team has been training farmers on the best practices for harvesting operations like winnowing, dehulling, drying and sorting. At the processing stage, the project has introduced farmers to the operation and maintenance of mechanized maize shelling machines in collaboration with organizations such as the GRATIS Foundation and PodMEDIA; while at the storage stage, the project has collaborated with partners to introduce farmers to hermetic storage to prevent damage by insect pests.

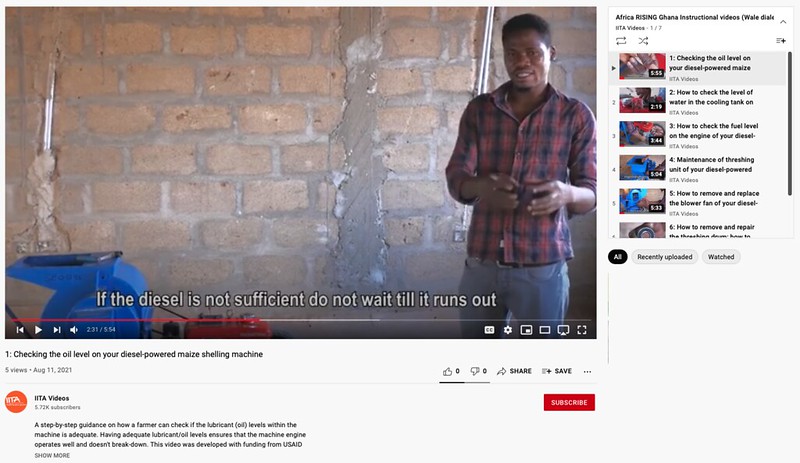

To enhance the gains made in the reduction of postharvest losses from these interventions, the Africa RISING project team has produced 35 short, vernacular do-it-yourself (DIY) videos that smallholder farmers can refer to for tips on maintaining their mechanized maize shelling machines. Produced in the five major local dialects spoken in northern Ghana – Gruni, Dagbani, Dagare,Wale and Kasim; the videos will be played for communal viewing and compressed in size and distributed through social media applications such as WhatsApp, whose usage within communities in the region is on the rise.

‘One of the main challenges we noticed since the introduction of the maize shelling machines to farmers is the limited access to qualified technicians for quick repairs whenever there is a breakdown. The majority of the technicians are based in urban areas and are sometimes too busy therefore forcing the farmers to interrupt their shelling activities several times and in the process leading to even more postharvest losses,’ explains Africa RISING Project Agricultural Economist Bekele Kotu. ‘As a project, our approach to solving this challenge was first to offer practical training to 3-4 farmers (para-technicians) drawn from 21 farmers’ groups that we work within the region on how to carry out basic repair and maintenance for the maize shelling machines. And second, to develop these videos, which we believe will guide these para-technicians in their efforts to accomplish their responsibilities whenever the machines break down or require regular maintenance. We hope that this will help the farmer to avoid lengthy interruptions of maize shelling activities due to machine spoilage in a situation where professional technicians are inaccessible,’ adds Bekele.

The videos offer step by step guidance on maintenance and repair, covering topics such as:

- Checking the oil level on your diesel-powered maize shelling machine

- How to check the fuel level in the engine of your diesel-powered maize shelling machine

- How to check the level of water (coolant) on your diesel-powered maize shelling machine

- Maintenance of the threshing unit of your diesel-powered maize shelling machine

- How to align and replace the belt and pulley of your diesel-powered maize shelling machine

- How to remove and replace the blower fan of your diesel-powered maize shelling machine

- How to remove and repair the threshing drum; how to grease chase bearings of your diesel-powered maize shelling machine

Through the Africa RISING project, 18 small-scale diesel-powered maize shellers have been granted to farmers’ groups in the Northern, Upper East, and Upper West regions. The farmers’ groups have been formed voluntarily by the farmers with the facilitation of Africa RISING project staff. Each group has developed a constitution to govern members’ interactions regarding the management and use of the machines and every member has made cash contributions to establish the initial capital.

In addition to cutting down the postharvest loss of precious grain, the mechanization of postharvest operations has also been shown to reduce the total labour time required for maize shelling by 96%. This is a significant advantage, particularly for women who shoulder much of the maize shelling burden in addition to enormous household chores.

Latest Comments